GAZC offers cutting edge technology

and state of the art production sites

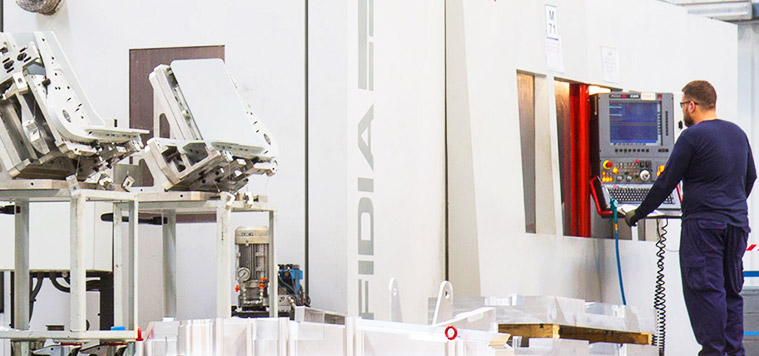

MILLING

- Automated machines

- Palletized machines

- Hard Metal – Soft Metal Production

- High-rate and low-rate Production

TURNING

- Dedicated workshop for turning activity

- Multi task turning machinery

- All materials (Steel, Titanium, Inconel, Cupper, Aluminum, non-metallic)

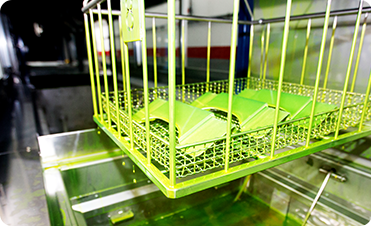

GLOBAL FINISHING

GAZC counts with an automatic surface treatment facilities covering a wide range of processes and approved by major OEMs.

List of processes:

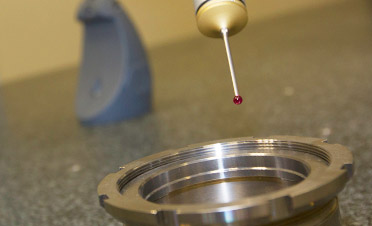

NON – DESTRUCTIVE TESTING

- Inspection by penetrating liquids

- Semi-automatic line

- Inspection by magnetic particles

- Conductivity and hardness measurement

SURFACE TREATMENTS

ALUMINIUM

- Automatic Process lines

- Main Processes

- Chromic anodizing

- Tartaric-sulphuric (TSA)

- Sulphuric Anodizing for Aluminium. Colours: Blue, red y black

- Chemical conversion film

- Boric Acid Anodizing

TITANIUM

- Automatic Process line

- Sulphuric Anodizing

STEEL

- Automatic Process line

- Cadmium plating (general and low fragility)

- Type I – Cadmium

- Type II Cadmium with chromating supplementary treatments

- Type III Cadmium with phosphating supplementary treatments

- Zinc Nickel Plating

- Passivation type I y II

SURFACE ENHACEMENT –

Shot Peening

Manual

- Shot-peening – “Steel shot”

- Shot- peening – “Glass beam”

Automatic

- Shot-peening – “Steel shot”

Heat Treatment

- Heat Treatment – Aluminium

- Stress Relief – Steel

Painting

- Automatic Carrousel

- 4 Painting Cabin + 4 Ovens (Dim. Max 4,000m)

Assemblies

GAZC counts with assembly capabilities and approvals for the a wide range of operations, including:

- Installation of Fasteners

- Installation of Bearings

- Sealing

- Riveting

- Crimping